"With the ambition to be the solar industry's preferred supplier of value-adding steel solutions, we must be capable of growing alongside our customers. This investment is a clear indication that we are taking action to match our commitments," states Carsten Damsgaard, Head of Sales.

There is no denying the growth of the solar industry. "Since the investment decision, our solar segment has expanded by 20 percent, and we don't anticipate a decrease in our solar activities in the coming years."

Specially Designed for the Solar Segment

The plant is simple to operate, extremely flexible, and aligns perfectly with the solar profiles that the roll forming line is primarily designed to produce.

The production line extends a total of 61 meters. It includes a feeding line with a double coil unwinder, 9-axis straightener, and fully automatic strip welding supplied by German firm, ARKU.

From the feeding line, the steel strip is passed onto a 100T Andritz/Kaiser pre-punching system that fabricates the hole pattern in the steel profile.

Subsequently, the steel strip is transported to the final profile shaping process. The roll forming line, supplied by Dreistern, comprises 28 flexible rolling stations, which are set up and prepared at an external station in production.

The profiles are then trimmed with a cut-off machine - also provided by Dreistern - before being transferred to the packaging line, designed by Ib Andresen Industri.

The new roll forming line for producing steel profiles for the solar industry will not be idle for long. From almost the first day, the line has been fully booked.

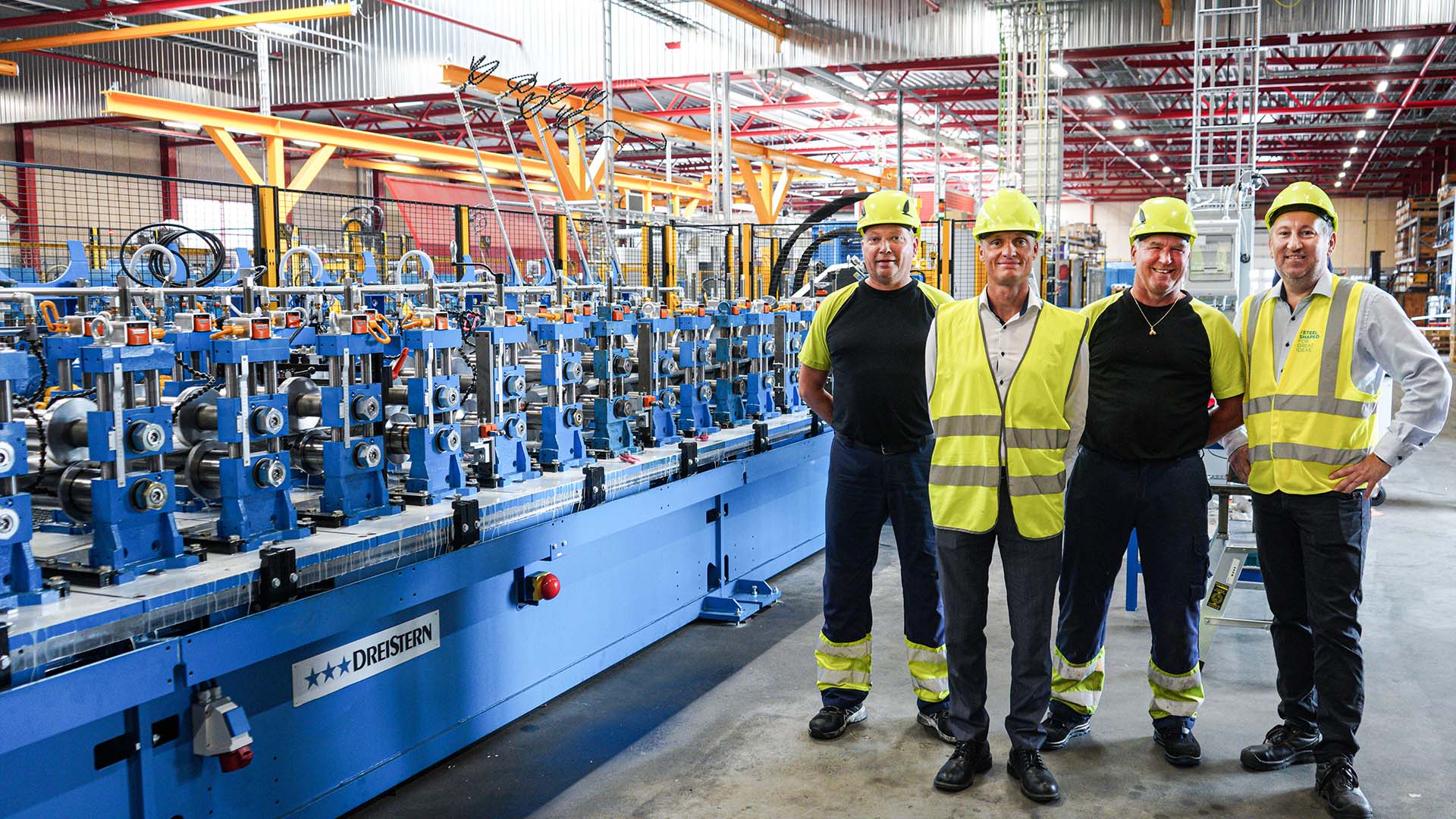

Photo / Left to right Mogens R. Olsen (Operator), Thomas H. Agergaard (Head of Operations Steel Solutions), Kim Lindensparre (Operator) and Carsten Damsgaard (Head of Sales)