Why choose our roll forming services?

Explore how our roll forming services make a difference below:

-

In-House Coil Slitting Facility: We not only slit coils into coiled strips but also store both coils and sheet metal, thus enhancing the reliability and flexibility of your steel profile supply chain.

-

Efficient Production: Our team offers valuable insights and recommendations to enhance the manufacturability of your products. Additionally, we provide the option to stock finished steel profiles, supporting cost-effective, large-batch production.

-

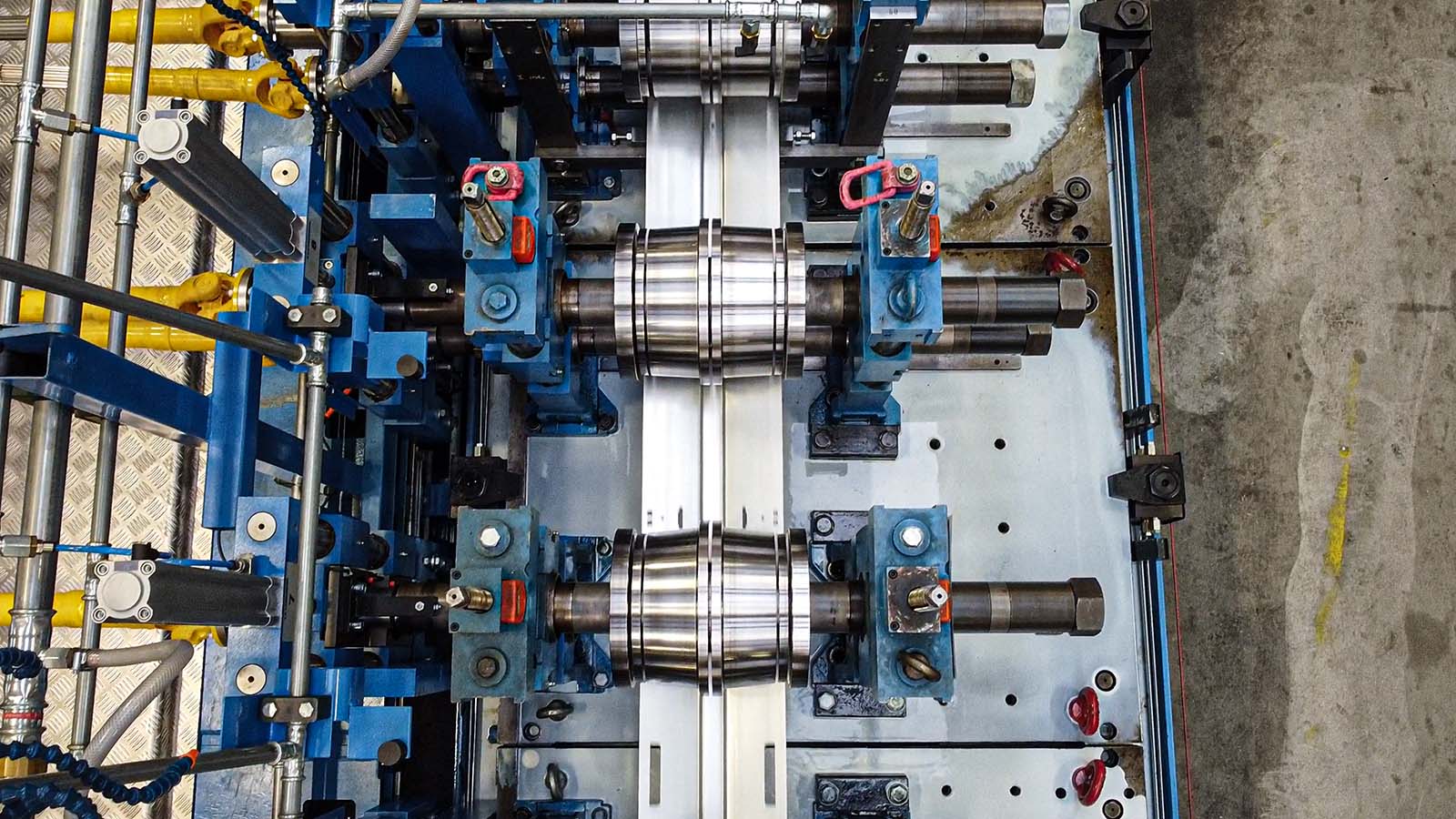

Modern Roll Forming Plant: Our diverse range of roll forming lines, operated by experienced professionals, can handle steel profiles of all types – big or small, simple or complex. See capabilities below.

-

Automation Emphasis: We are consistently enhancing our roll forming plant, focusing on both upgrading existing lines and introducing new ones. Our primary goal is to increase automation levels.

-

One-stop Shopping: We handle your steel profile's entire value chain, from the steel mill to manufacturing, with additional third-party services and delivery. We guarantee just-in-time delivery to your production line or on-site.

Our roll forming capabilities:

|

Material thickness: |

0.25 - 7.0 mm |

|

Band width: |

20 - 1,000 mm |

|

Length of steel profiles: |

150 - 16,000 mm |

Roll forming services - part of a value-creating concept

Our approach extends beyond roll forming services. It involves co-engineering, an independent steel service center, advanced sheet metal processing, dependable logistics, and precision delivery. We also prioritize sustainability through our value chain, and employ dedicated project management and robust quality assurance to exceed your expectations.

Discover more about our comprehensive approach here.