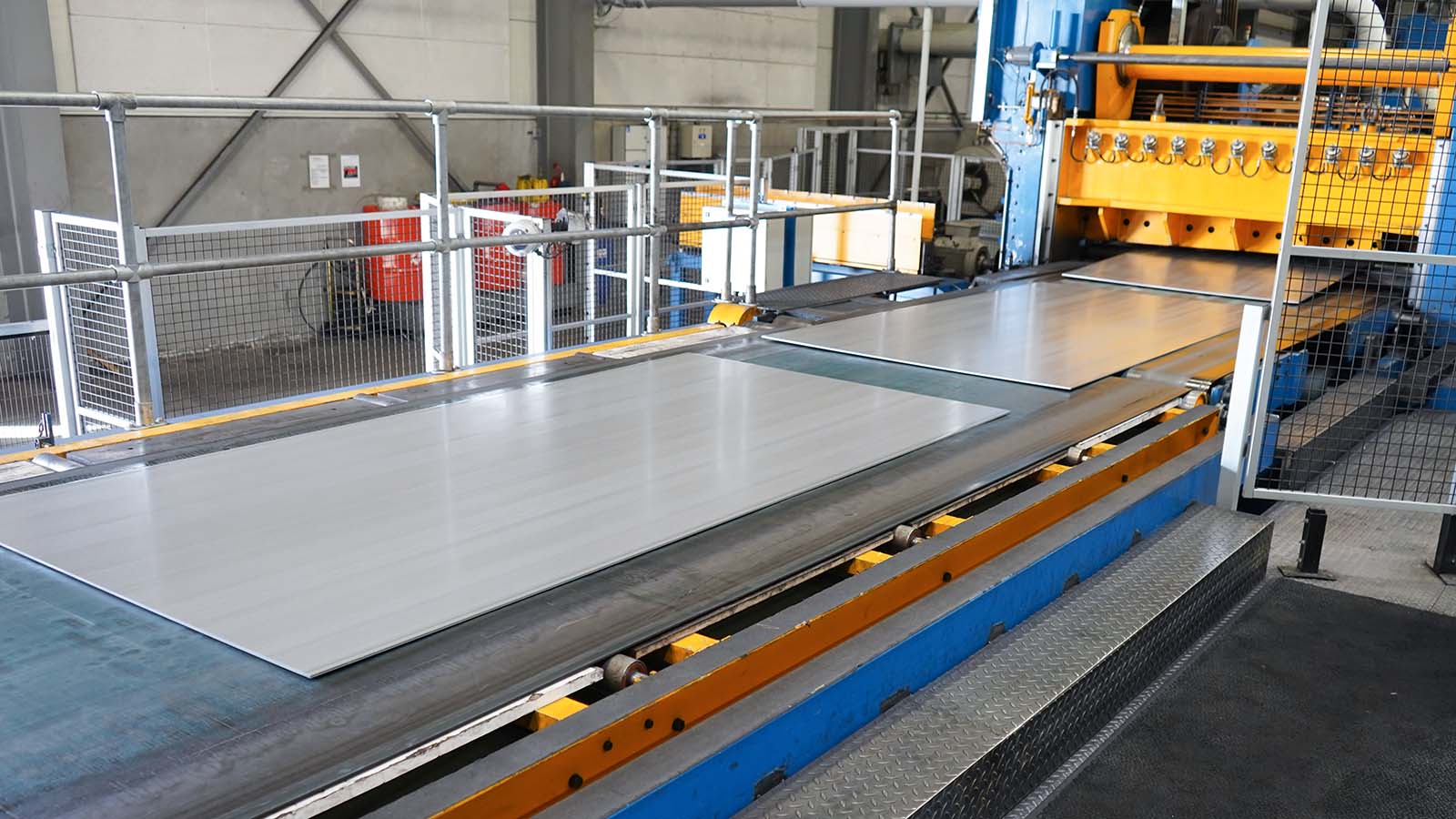

Our independent steel service center provides cut-to-length and coil slitting services

Explore why Ib Andresen Industri is a go-to provider for cut-to-length and coil slitting services:

-

Unparalleled Expertise: Our Steel Service Center boasts a team of specialists adept in the art of transforming large coils into cut-to-length sheet metal and precision slit steel strips, handling up to 30-tonne coils.

-

Capacity and Flexibility: Our comprehensive knowledge, combined with expansive capacity, guarantees that we meet the steel industry's demand for unparalleled quality, exceptional flexibility, and unwavering delivery reliability.

-

Customized Storage and Logistics: Beyond cut-to-length and coil slitting, we offer fully automated coil storage and create tailored storage and logistics solutions to suit your specific needs. You can also rely on us for stocking and shipping your cut-to-length sheet metal and slit steel strips directly to your customers.

-

Strategic Location: Our independent steel service center is strategically located in the heart of Northern Europe, in proximity to major ports, railways, and motorways. This advantageous location allows you to source steel from mills across the globe seamlessly.

-

Digital Transparency: Leveraging our innovative extranet solution, you gain instant online access to your inventory (coils, sheets, slit strips), orders, shipments, and more.

-

Complete Traceability: Rest assured, we provide complete traceability from the steel mill to the final product.

Our cut-to-length

|

Our coil slitting

|

|

Material Thickness: |

Material Thickness: |

|

Sheet/Plate Width: |

Coil Width |

|

Sheet/Plate Length |

Ring Width |

|

Coil Weight |

Coil Weight |