This initiative is the first in a series of planned upgrades aimed at increasing flexibility, capacity, and value creation for both existing and new customer groups—while simultaneously strengthening the company’s position in a market with growing demands for speed and delivery reliability.

“Our ambition is to be the partner customers choose when operational reliability, capacity, and development capability across the value chain are critical. Upgrading our laser capacity is an important step toward realizing that ambition,” says Head of Sales, Lars S. From.

A Technological Upgrade with Commercial Impact

The new fiber lasers increase cutting speed, process stability, and the ability to handle both thicker and larger workpieces. Although older equipment is being phased out, total production capacity will increase significantly. This enables faster changeovers, shorter lead times, and a higher level of process robustness in day-to-day operations.

For customers, this translates into greater flexibility—whether for prototypes, small batches, or high-volume production.

Ambition to Reach New Markets

The upgrade supports the company’s ambitions to expand its market position. Increased capacity and a more stable process make it possible to serve new segments and strengthen presence in industries where high quality standards and short lead times are key competitive factors.

“We see a growing demand for suppliers who can combine efficient production with strong technical expertise. With this technological upgrade, we are better positioned competitively—and able to meet a broader range of market needs,” Lars S. From elaborates.

New Ownership Opens the Door to Synergies

The initiative is also part of the company’s strategic development following the change in ownership. Upcoming collaboration between activities in Denmark and Germany will open up synergies in both technology and capacity—creating a stronger, more comprehensive offering to the market.

Technological Upgrade: Higher Power, Larger Format, and a More Stable Process

With the two new fiber laser machines supplied by Bystronic, Ib Andresen Industri, as mentioned earlier, significantly increases both power levels and capacity. The machines deliver 12 kW and 15 kW respectively, ensuring higher cutting speeds, more stable operation, and the ability to process thicker materials in carbon steel, stainless steel, and aluminum.

At the same time, the cutting tables have been upgraded from the previous 1,500 × 3,000 mm format to 2,000 × 4,000 mm. This allows more flexible utilization of steel plates, reduces material waste, and makes it possible to handle larger components in a single setup. For customers, this means shorter throughput times and fewer limitations on part size.

The machines also feature advanced automation functions, including automatic nozzle changing, automatic beam centering and focusing, and KerfScan, which continuously monitors cut quality and automatically adjusts the process to ensure consistent results. In addition, mix gas technology—combining nitrogen and oxygen—delivers sharper cut edges and a more stable cutting process without compromising speed.

Overall, these technical enhancements provide a significant boost in precision, process robustness, and throughput—resulting in a more scalable and competitive production setup capable of meeting both complex and high-volume customer requirements.

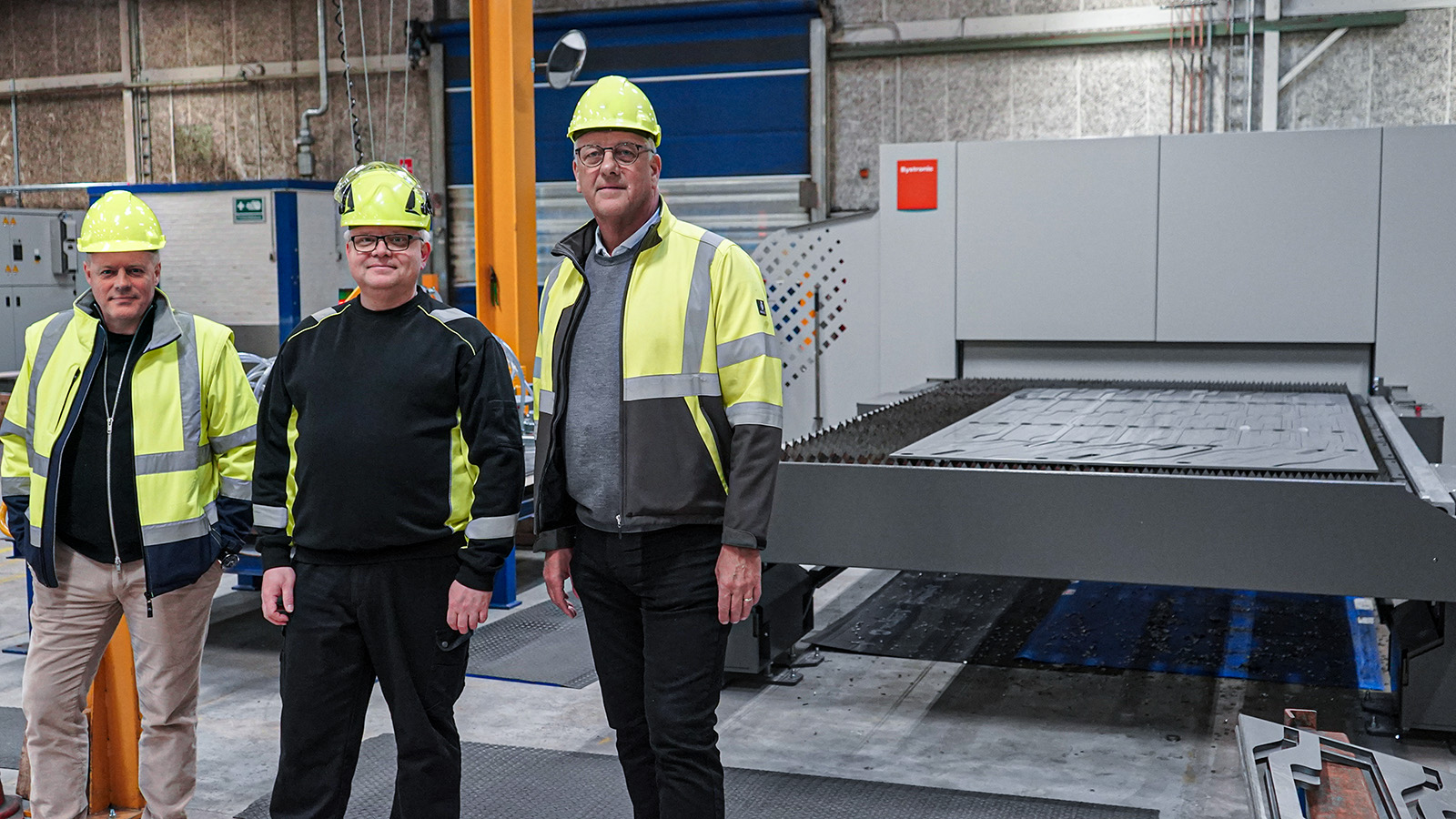

Photo: Head of Sales Lars S. From (left), Technical Supporter Jan V. Aarosiin, and Head of Operations Hans Jørgensen.