Your idea was to realize the world's longest immersed tunnel: the Fehmarn Belt connection

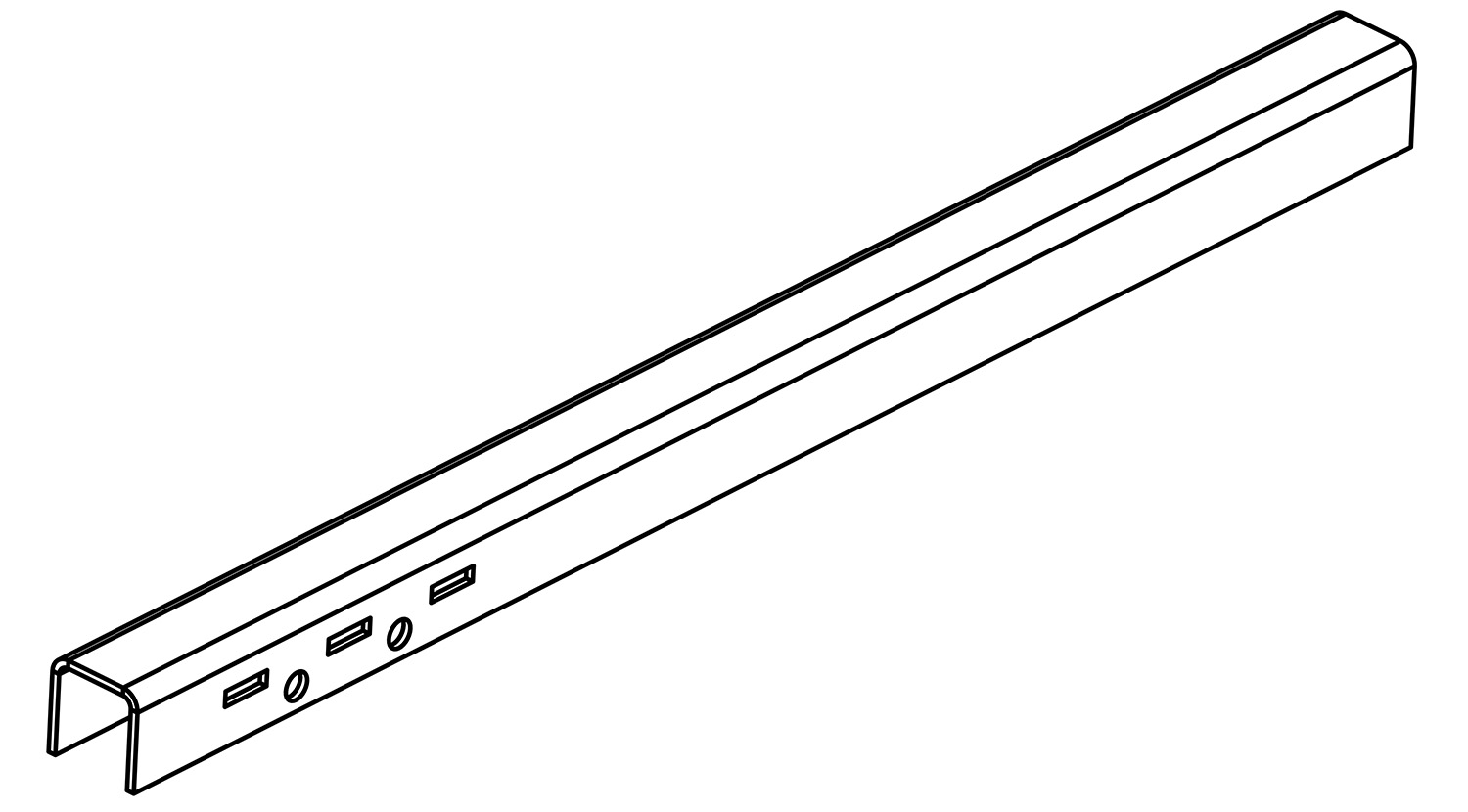

We provide support modules for the reinforcement steel in the tunnel elements' concrete construction. This ensures an efficient and consistent production of all 89 tunnel elements.

Here's how we assist Femern Link Contractors:

We've leveraged our experience in large-scale construction projects and deployed our value-based services, including fully automated roll forming combined with modern welding cells to ensure quality, as well as coordination of daily logistics, all the way to the Rødbyhavn on-site location, just-in-time.

All of this is managed by dedicated project managers, customer support staff, operators, and logistics personnel across all our departments.

By investing in fully automated welding cells, we enable 800 meters of welding per day. This ensures the necessary capacity to support Denmark's largest construction project in history.

The support modules for the 89 standard tunnel elements consist of a total of 711 steel segments and weigh approximately 30,000 tonnes.

Within these 711 segments, there are 180,000 welded frames. A tunnel element is 217 meters long, 42 meters wide, 10 meters high, and weighs 73,500 tonnes.